So—is it a 9 or is it a 6?

Depends on who’s looking at the problem. You’ve probably seen memes similar to this that call out how we can become entrenched in our different perspectives. But some read this picture to mean no one is wrong. They even go so far as to say, “There are no objective truths.”

I don’t agree. I think this point is where hard and necessary work must be done, because there actually is a perspective we should agree on and accept in the workplace. Having a diversity of ideas about the way things should be done is important, but that doesn’t mean we leave meetings allowing those competing ideas to carry us off in a hundred different directions. Instead, we must decide on the best ideas and work together.

But this important step is often left undone. I call this oversight a lack of organizational focus.

Freedom to interpret the mission individually leads to chaos throughout the organization.

Of course, my area of expertise is applying lean manufacturing principles to business processes. I take the traditional seven lean wastes (read my earlier post on this topic) and translate them for transactional, administrative, or knowledge work. On a manufacturing assembly line, shop floor, or hangar floor, I believe there’s almost always a clear organizational focus. That’s partly because the work is routine, and partly because it’s highly visual. You can actually see incomplete or undone work, which creates its own sense of urgency.

But in an office, the work and the intent are mostly invisible—especially now, with so many people working remotely. That’s why I add an eighth waste for the business office: a lack of organizational focus. In fact, for knowledge work, it’s likely the biggest waste of all, and the root cause of all the others. Without a visual focus, there’s no sense of urgency. And even if there’s a mission statement written at the highest level, it’s often left to be interpreted by everyone down the chain. (I’ve even seen major impasses in organizations because different levels of the organization interpreted a single word differently.) This causes conflict, which often becomes personal and personality-driven.

The Telltale Signs of a Lack of Organizational Focus

- The mission and vision have not been articulated, documented, and communicated for your work area.

- There’s no situational awareness of your constraint, or you haven’t performed a Pareto analysis, so the team is not focused on the important few, but instead distracted by the trivial many.

- Instead of a common mission and vision, you have a de facto mission in its place, such as a false sense of urgency to answer emails within the hour, or spend all the budget before the end of the fiscal year.

- The only sense of urgency you feel as a team is at the end of the month, quarter, or year, when you find yourself with a goal to meet one metric without its balancing metric. Every department ends up optimizing itself at the expense of the whole, while compromising quality and sometimes integrity.

- Heroes are allowed to hoard information and hold the organization hostage.

- You don’t pay any attention to common cause versus special cause variation, so you find yourself chasing two dots on a run chart when most likely the variation is just noise.

- Lacking focus, you start too many projects, so work in process goes up, lead time goes long, and customer satisfaction goes down. The next domino is either batching or multitasking (which, as you may remember, is “worse than a lie”). Each person is allowed to perform work and even create outcomes differently.

- You’re micromanaging or being micromanaged. No true north has been set, so employees can’t self-correct and managers constantly interrupt.

Why does this happen and continue to be the status quo at most large organizations? A book I’m reading offers one explanation*:

…managers love complexity. Complexity is stimulating and intellectually challenging; it leavens boring routine; and it creates interesting jobs for managers. Some people believe that complexity obtrudes when no one is looking. No doubt—but complexity is also sponsored by managers, just as it sponsors them. Most organizations, even ostensibly commercial and capitalist ones, are conspiracies of management against the interest of customers, investors, and the outside world generally. Unless firms are facing an economic crisis or have an unusual leader who favors investors and customers rather than his or her own managers, excess management activity is virtually guaranteed. It is in the interests of the managerial class in charge. (The 80/20 Principle: The Secret to Achieving More with Less, by Richard Koch)

This quote is the most concise reason I’ve read since Parkinson’s Law for why bureaucracy exists. I see evidence of this phenomenon every time I facilitate flow simulations in class.

Well—Which Is It?

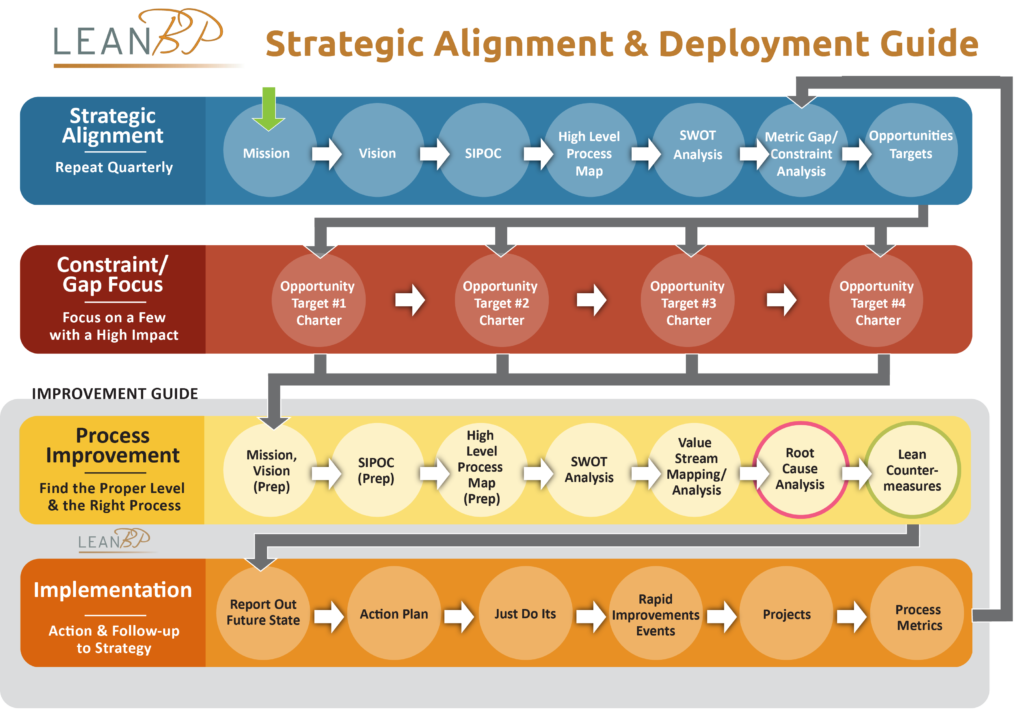

How do you determine if you’re looking at a 9 or a 6 and get back to a common purpose? Work the blue line—the top line of the LeanBP Strategic Alignment and Deployment Guide. Taking input from customers and your hierarchy (the green arrow), articulate the purpose for your existence, then a vision of how well (or how much better) you should be performing within 6–12 months. (If you’re the one facilitating, be sure this is recorded in a charter, or your improvement efforts will derail very quickly.)

To help create common situational awareness, develop a SIPOC (Suppliers, Inputs, Policies, Outputs, Customers), which is a five-column table that sums up your job. I’ve worked with large and small departments and organizations that had no idea they didn’t agree on who the customer was (9 or 6?) until they went through this exercise. Seeing a process at a high level helps create common perspective. And, finally, performing a SWOT analysis (Strengths, Weaknesses, Opportunities, & Threats) helps you “see” the intangibles together.

It’s also helpful to have a consensus of values—to agree on the way you will act, or not act, while striving for your objectives. The Toyota Production System (lean) cites “Respect for People,” and I also suggest using the Disciplines of Speed, which prioritizes your values. Of course, we strive to achieve productivity and economy, but never at the expense of integrity, compliance, or quality.

- Integrity

- Compliance

- Quality

- Productivity

- Economy

Get the Ball Rolling

When should you start? Now! Why continue to go further off course or allow your employees to do so? Create a prototype—then share with your boss, your subordinates, and peers. This is what we call “catchball,” a back-and-forth volley of ideas. This is best done using the methodology of single-text negotiation—editing the projected document together at the same time.

With a common purpose, vision, and understanding of situational awareness, you’ll find you finally agree on 9 or 6! Economist Friedrich A. Hayek once said, “. . . . We are able to bring about an ordering of the unknown only by causing it to order itself.”** This most important work is the cure for lack of organizational focus.

I’ve seen this exercise create spontaneous order out of chaos, whether it was chaos in just one person’s mind, on a project team, or across an entire department. Once colleagues were aware of the focus (the desired outcome or goal) and achieved situational awareness, they could then become creative on how to solve the common problem or execute the strategy without micromanagement. I can even name a few process improvement events that were canceled because once the focus was created, the sponsor found the problem was not systematic, but was instead fairly simple to solve.

If you’d like a complete template of the blue line exercise to guide you as you work, email me. Work completing the first draft into your daily routine and then update it as the organizational situation changes. If you’re stuck in an organizational situation you can’t control because you aren’t the boss, be the boss of you. Determine your circle of influence and share accordingly for consensus.

Or do you secretly love complexity?

*Koch, Richard. The 80/20 Principle: The Secret to Achieving More with Less. Crown Publishing Group, New York, 2008.

**W.W. Bartley, ed. The Collected Works of F.A. Hayek. University of Chicago Press, Chicago, 1988.

Good blog.

Comments are closed.